Preparation: Workflow Checking

We recommend you check and modify, if necessary, your OpenText PPM workflows against the Quality Center workflow before you upgrade the integration configuration.

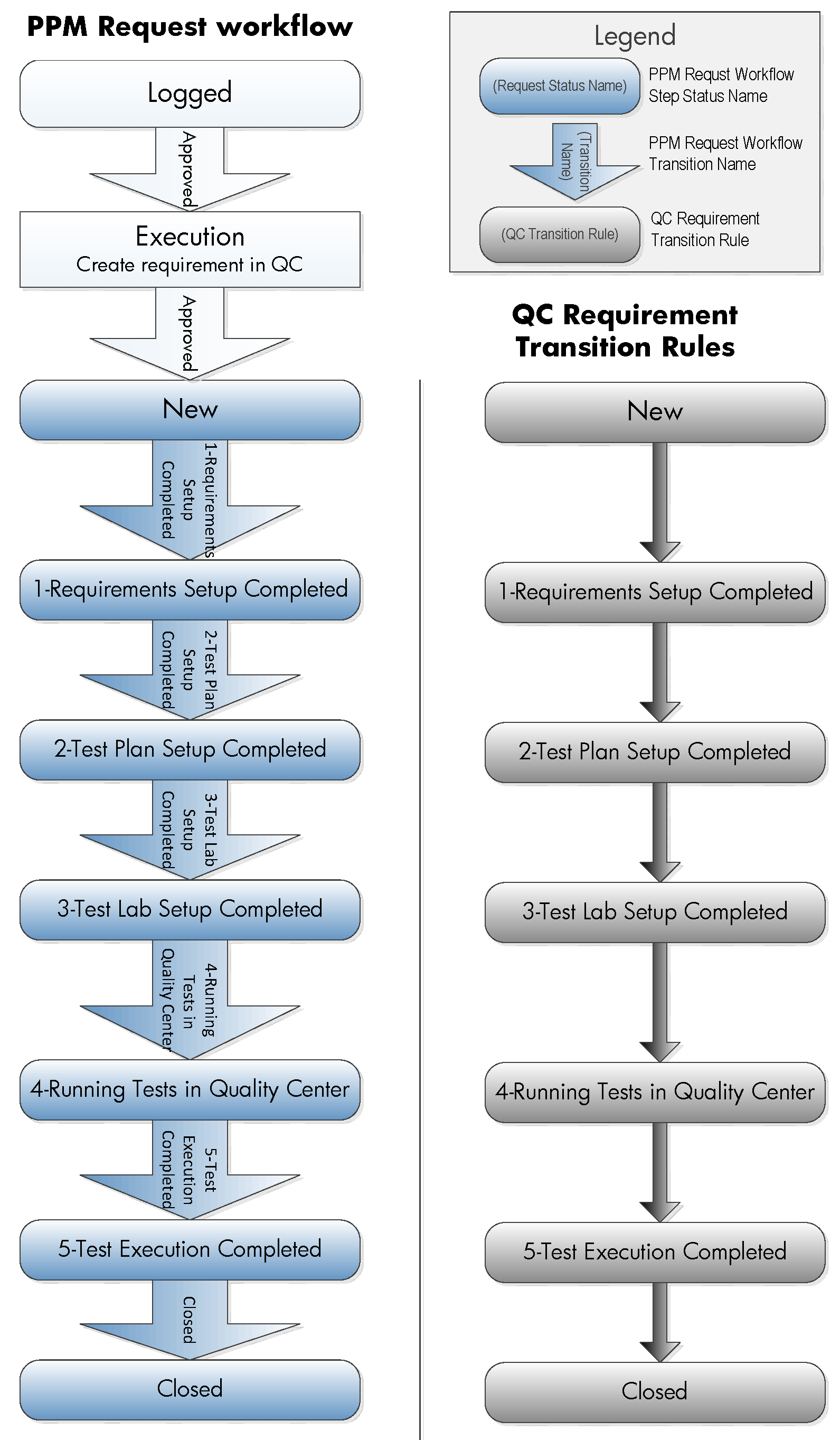

Figure 6-3. An example of PPM request workflow steps statuses matching QC requirement transition rules

For an existing integration with Quality Center 10.00, you can use the OpenText PPM-Quality Center Integration Tool to perform integration configuration. As a result, for example, the workflow related hardcoded configuration can overwrite the workflow script in Quality Center. Then, you can set the control mode to PPM, so that PPM request workflow execution drives the synchronization of PPM request status to Quality Center requirement status.

However, with ALM 11.x or later, due to its policy changes, you are no longer allowed to overwrite ALM's workflow script to enforce the PPM workflow execution.

To achieve bidirectional status synchronization between PPM request and QC defect or requirement, go to PPM Workbench to check and make sure that your PPM request workflow steps are exactly consistent with the transition rules defined in Quality Center.

For example, you have an integration configuration and you create a request in OpenText PPM to create a requirement in QC. The OpenText PPM request follows the workflow illustrated in the left part of Figure 6-3, and the requirement follows the default transition rules in QC (right part of Figure 6-3).

You need to ensure the following for status synchronization between PPM request and QC/ALM defect or requirement to work properly:

-

For successful status synchronization from PPM to QC/ALM, the statuses and sequence of PPM request workflow steps shall be exactly the same as those of transition rules in QC/ALM.

For example, in PPM request workflow of Figure 6-3, status of the step following the Execution Create a requirement in QC step shall be New, as the first requirement rule in QC is New. If you provide a different status description, such as New1, the status synchronization from PPM to QC would be lost.

Note: For a defect workflow, status of the step following the Execution Create a defect in QC step shall be New.

For detailed descriptions and sequence of transition rules defined in QC/ALM, check the TRAN_RULES table in the QC/ALM project schema database.

-

For successful status synchronization from QC/ALM to PPM, in addition to ensuring that the statuses and sequence of PPM request workflow steps are exactly the same as corresponding transition rules in QC, you also need to ensure that in PPM request workflow, the description of a transition is exactly the same as the status of the subsequent request workflow step.

If, for example, you provided a transition description that is different from its subsequent step status, you would lose synchronization of status from QC to PPM after upgrading your integration configuration to PPM Center 9.14 and ALM 11. However, you can still click Save to update other fields, such as Summary and Description, though with error message displayed.

Note: For defect workflow, by default the setting in the TRAN_RULES table of QC is

$ANYto$ANY. If there are custom rules instead, see the example on requirement in this section.

Note that if your workflow is the same as the example illustrated in Figure 6-3, we recommend you manually deploy the configuration file (ITGQCIntegration.xml) again by using the OpenText PPM-Quality Center Integration Tool. For detailed instructions, see Deploy the Mapping File to OpenText PPM and QC.

If you are using customized workflow in QC, modify the PPM Center request workflow in the PPM Workbench before you perform the upgrade process.

For answers to any other potential questions you may have regarding the upgrade process, see Frequently Asked Questions and Answers.